Pharma Pellet Making Machine

Product Details:

- Type Other

- Material Stainless Steel

- Capacity as per your requirement T/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 Volt (v)

- Power 3 PHASE Volt (v)

- Click to View more

Pharma Pellet Making Machine Price And Quantity

- 1 Unit

Pharma Pellet Making Machine Product Specifications

- 440 Volt (v)

- 8 x 8 x 5 Foot (ft)

- Silver

- Yes

- 3 PHASE Volt (v)

- Other

- Stainless Steel

- 1 Year

- as per your requirement T/hr

- 500 kgs Kilograms (kg)

- Automatic

Pharma Pellet Making Machine Trade Information

- MUMBAI JNPT PORT

- 4 Unit Per Month

- 6-8 Week

- sea worthy packing

- Eastern Europe, Central America, Africa, Middle East, South America, Western Europe, Australia, Asia, North America

- All India

Product Description

Owing to our wide thorough expertise in this domain, we are engrossed in manufacturing and exporting Pellet Making Machine. These machines are engineered understanding the variegated requirements of the market. Our offered machine is equipped with premium quality components, which are procured from the reliable vendors of the market. The offered Pellet Making Machine is available for the customers in different sizes and specifications, so as to suit their varied demands.

Features:

- Fine finishing

- Rugged construction

- Easy to operate

PALLET MAKING MACHINE

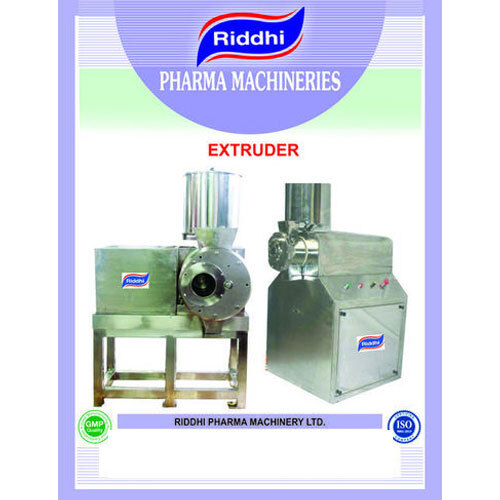

We are one of the pioneer Pharmaceutical Machinery Manufacturers from India, We manufacturer Pallet Making Machine, which is called Extruder, from the extruder small sticks are achieved. Which are further put into sperodiser for achieving pallets, which are used for drug layering of sustained release products.

Technical Offer

The product to be converted is prepared in the form of a dough with binder/moisture, and is feed in the Extruder. The die roller design of extruder operates with two rollers. One is the Knurling (pressing) roller and other is the die roller. The perforation size of the roller decides the size of the needle / granules & hence the size of Pellets to be formed. The size of the extrusions that come out are finite length with the help of a adjustable cutter attached.

The twin screw design of extruder operates with a set of conveying screens which transfer the material to the pressing cams which further press the material to a particular size of mesh. The size of the noodles is decided from the size of the Die mesh fixed.

The spheres obtained from the twin screw design has lesser bulk density compared to pellets produced by the roller design extruder. In other words the compressional forces that act in a die roller design extruder are for more than the other resulting in compact and DENSE pellets. It again depends upon applications & product chooses the correct machine for the optimum utility.

Technical Specification

| Model | Output (Kgs/Qa) | Motor HP | Die Roller Perf |

| RDETD 65 (lab) | 2-4 | 1 | 0.8-3 |

| RDETD 65 | 10-15 | 1.5 | 0.8-5 |

| RDETD 65 | 15-25 | 2 | 0.8-5 |

| RDETD 100 | 50-90 | 5 | 1-7.5 |

| RDETD 130 | 200-300 | 7.5 | 1.5-10 |

| RDETD-60 | 20-30 | 2 | 0.6-5 |

| RDETD-100 | 60-100 | 5 | 0.6-7.5 |

| RDETD-130 | 250-350 | 7.5 | 0.6-10 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free