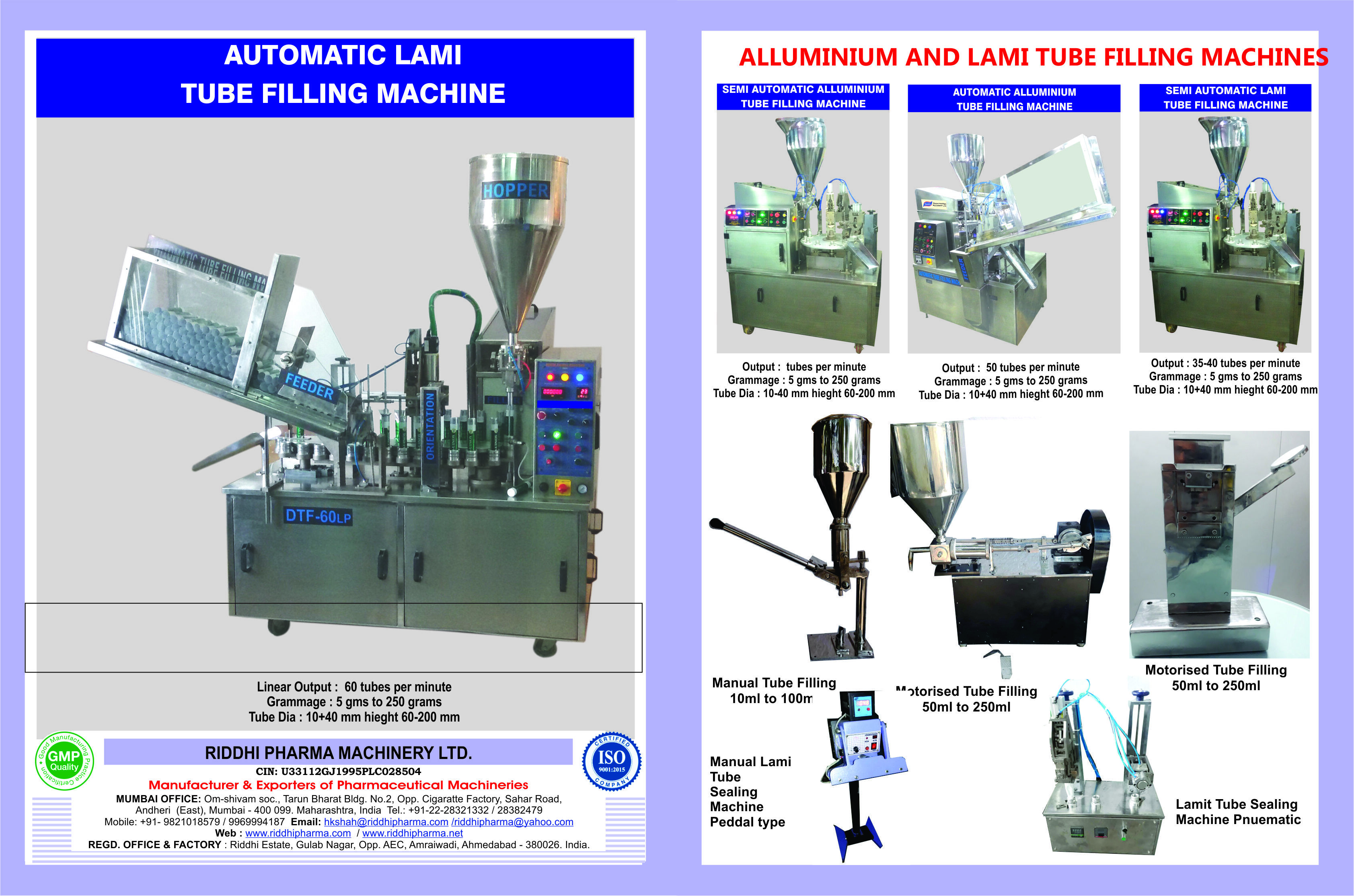

AUTOMATIC TUBE FILLING AND SEALING MACHINE

1500000 INR/Unit

Product Details:

- Type Pharmaceutical Packaging Machine

- Material Stainless Steel

- Capacity 20 to 100 tubes per minute Kg/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 volts Milliampere (mA)

- Power 3 phase Milliampere (mA)

- Click to View more

X

AUTOMATIC TUBE FILLING AND SEALING MACHINE Price And Quantity

- 3 Unit

- 1500000 INR/Unit

AUTOMATIC TUBE FILLING AND SEALING MACHINE Product Specifications

- Silver

- 6 x 6 x6 Foot (ft)

- 275 kgs Kilograms (kg)

- 3 phase Milliampere (mA)

- 440 volts Milliampere (mA)

- Automatic

- Stainless Steel

- Yes

- Pharmaceutical Packaging Machine

- 20 to 100 tubes per minute Kg/hr

- one year warranty

AUTOMATIC TUBE FILLING AND SEALING MACHINE Trade Information

- MUMBAI JNPT PORT

- 1 Unit Per Month

- 6-8 Week

- SEA WROTHY PACKING

- All India

Product Description

Fully automatic, single head, fully enclosed GMP model type tube filling and sealing machine.

The salient feature and the scope of supply is as follows.

General

- The speed of the machine is upto 60 tubes per minute. It will vary depending upon the size and type of product the tube.

- It can fill up to 200ml of cream.

- It can seal tube up to 40mmdia tubes.

- It will have oval race track with Aluminum tube holder.

- The indexing system will be ofFerguson type oil immersed.

- The body is fully enclosed from all sides.

- The machine will be cladded with pre-buffed SS sheet.

- Over load protection of Conveyor.

Tube in- feed

- Cassette type Tube Magazine in feed unit. The entire tube box will be emptied in the cassette and one by one tubes will be fed in to the machine.

- The in feed unit will consist of inclined chute, vacuum assisted tilting mechanism and mechanically controlled push rod for automatic insertion of tubes in tube holders.

- A separate switch for tube loading/stop command.

- Vacuum pump will be provided for assisting tube transfer.

Print mark registration unit

- A very accurate print mark registration unit will ensure correct positioning oif tubes.

- It will work on stepper motor and its controller.

- Contrast scanner will be of Wenglore or Sick make.

FillingValve

- Capable of filling liquid,semi viscous and viscous product.

- All the contact parts to product will be of SS 316L.

- Dosing is volumetric.

- Rotary valve spool will berotated pneumatically.

- Dosing capacity from 3ml to200 ml. Change in volume is carried out with change of cylinder and piston.

- One set of cylinder and piston forms the part of standard supply.

Injection Nozzle.

- It consist of nozzle and shutter rod prated pneumatically.

- Fill is bottom up.

- Combination of Air blow andpositive shutter rod ensures drip free cut off.

- The unique feature is that the nozzle block height is adjustable. This ensures the correct position of cutoff in the tube.

Hopper

- The Hopper will be of SS316of 45 lit capacity. And will have stirrer fitted.

- The hopper will jacket forheating the product.

- Ultrasonic level sensor will be provided on the hopper.

Sealing and Trimming.

- The sealing unit will be hotair type which can seal lami as well as plastic tube.

- The heating system by Leistermake Switzerland 3300 watt heating Gun controlled by electronicthermo regulator.

- The trimming/sealing unit willsealing unit will be pneumatically operated.

- Cutting blade made of Highspeed steel.

- One set of Digits 5 nos. each consist of 0 to 9. And Alphabets as required.

- Central hand wheel to adjust the height of the sealing and cutting unit.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free