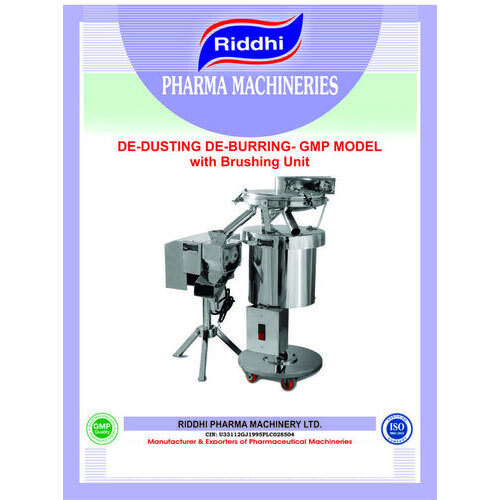

TABLET DEBURRING DEDUSTING MACHINE

Product Details:

- Type Tablet Pressing Machine

- Material tablets

- Capacity upto 2,00,000 tablet per hour T/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 VOLTS Volt (v)

- Power 3 phase Volt (v)

- Click to View more

TABLET DEBURRING DEDUSTING MACHINE Price And Quantity

- 65000 INR/Unit

- 3 Unit

TABLET DEBURRING DEDUSTING MACHINE Product Specifications

- ONE YEAR WARRANTY

- upto 2,00,000 tablet per hour T/hr

- tablets

- 440 VOLTS Volt (v)

- Yes

- 75 kgs Kilograms (kg)

- Tablet Pressing Machine

- STAINLESS STEEL

- Automatic

- 1.5 x 1.5 x2.5 Foot (ft)

- 3 phase Volt (v)

TABLET DEBURRING DEDUSTING MACHINE Trade Information

- MUMBAI JNPT PORT

- 4 Unit Per Month

- 4-6 Week

- SEA WORTHY PACKING

- All India

Product Description

Specification

| Capacity | DEPENDING ON TABLET SIZE |

| Usage/Application | TABLET DEDUSTER |

| Machine Capacity | depending on tablet diameter and size contionous type |

| Automatic Grade | Fully-automatic |

| Power (HP) | 0.5 kw |

TECHNICAL SPECIFICATIONS :

| Model | RDDB-300 |

| Output | 5,000 to 2,50,000 tablet / Hr. |

| Electric Motor | 0.25 Hp. / 3 Phase / 1440 RPM / 440 V. |

| Electric Motor (Brushing Unit) | 0.25 Hp. / 3 Phase / 1440 RPM / 440 V. |

| Max. Tablet Diameter | 40 mm |

| Min. Tablet Diameter | 5 mm |

| Net weight (Approx.) | 125 Kgs. |

| Gross weight (Approx.) | 275 Kgs. |

| Overall Dimension (mm) | 400 (L) x 530 (B) x 800 (H) |

| Overall Dimension (mm) With Brushing Unit | 500 (L) x 630 (B) x 900 (H) |

| Case Dimension (mm) | 500 (L) x 630 (B) x 900 (H) |

| Case Dimension (mm) With Brushing Unit | 500 (L) x 500 (B) x 900 (H) |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+