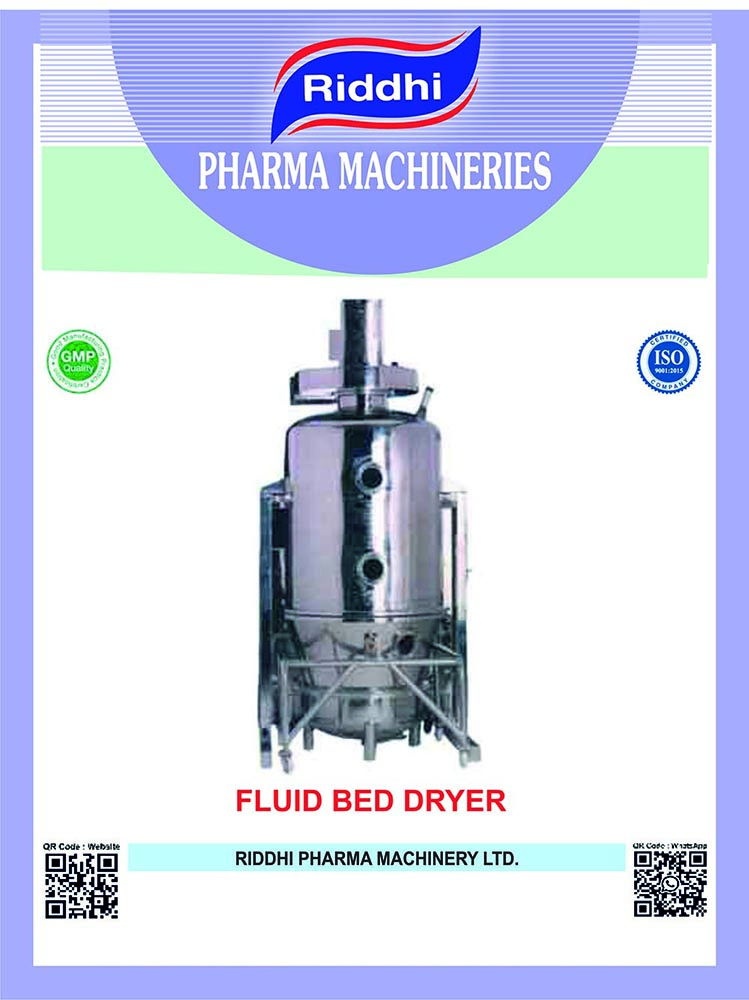

Fluid Bed Dryer

Product Details:

- Type Other

- Material STAINLESS STEEL

- Capacity LAB MODEL TO 500 KG Kg/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 VOLTS Volt (v)

- Power 3 PHASE Volt (v)

- Click to View more

Fluid Bed Dryer Price And Quantity

- 450000.00 INR/Unit

- 3 Unit

Fluid Bed Dryer Product Specifications

- Yes

- 440 VOLTS Volt (v)

- LAB MODEL TO 500 KG Kg/hr

- STAINLESS STEEL

- 350 KGS Kilograms (kg)

- 5 X 5 X 9 Foot (ft)

- Other

- 3 PHASE Volt (v)

- STAINLESS STEEL

- Automatic

- ONE YEAR WARRANTY

Fluid Bed Dryer Trade Information

- MUMBAI JNPT PORT

- 4 Unit Per Month

- 4 Week

- No

- SEA WORTHY PACKAGING

- All India

Product Description

RIDDHI introduces one of the finest Pharmaceutical Fluid Bed Dryer unit providing compactness and conceptional principle of Air Fluidization for drying granules crystalline coarse or similar materials in Pharmaceuticals Fine Chemicals Dyes Food Allied Industries

The basic concept of the Fluid Bed System begins with a simple Drying unit to which several different optional packages may be added for conversion to a granulation or coater

Process control system ranges from standard pneumatic logic to sophisticated computerized controls Air handling equipments can vary from the basic compact prefilter and heater to the system which provides complete control of the condition of the processing air This higher technology of process involved many modern technologies and to match that RIDDHI introducing conventional Fluid Bed Dryer

Advantages

The conventional drying method for drying products in tray dryers is rather inadequate troublesome They also occupy large space have very high uneven drying times and also involved high labour input To over come this problem RIDDHI made Fluid Bed Dryer which is the simple solution to dry the products

Suit abilities

This compact unit is suitable for drying granular crystalline coarse or similar materials in Pharmaceuticals Dryer Fine Chemicals Food Allied Industries It is also possible to dry fine crystal or coarse materials in fluid bed dryers

Special features

- Uniformity in drying and reduction in drying time

- Atmospheric inlet air is filtered by means of single multi stage filters of 20 microns to prevent any fine dust to pass through the product

- Steam Coil made out of 1 dia SS 304316 finned tube is designed to get pressure of around 34kgcm2 working pressure 3 kgcm2

- Digital temperature indicators cum controller is provided with the unit to indicate the inlet and outlet air temperature as well as to controller the present inlet air temperature

- Air suction and discharge dampers provided to control the inlet and outlet air flow

- An explosion safety flap of adequate capacity at the rear end of the dryer and an positive earthing point to prevent static charge in the machine are provided

- Timer provided to set the process time which will cut off the motor supply after preset time period

|

Model |

RDFD-15 |

RDFD-30 |

RDFD-60 |

RDFD-120 * R |

DFD-200 * |

RDFD-250 * |

|

Container Volume : Liters |

50 |

100 |

220 |

430 |

590 |

730 |

|

Batch Capacity : Kgs |

15-20 |

30-40 |

60-75 |

120-140 |

200-225 |

250-280 |

|

Heating Load : KW for Electrical Heating |

9 |

18 |

36 |

60 |

-- |

-- |

|

Motor H.P |

3 |

5 |

10 |

15 |

20 |

25 |

|

Drying Temp deg C |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

|

Appx. Steam Comsumption Kgs/hr. (Steam pressure 3Kg/cm 2) |

15 |

25 |

50 |

100 |

160 |

200 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free