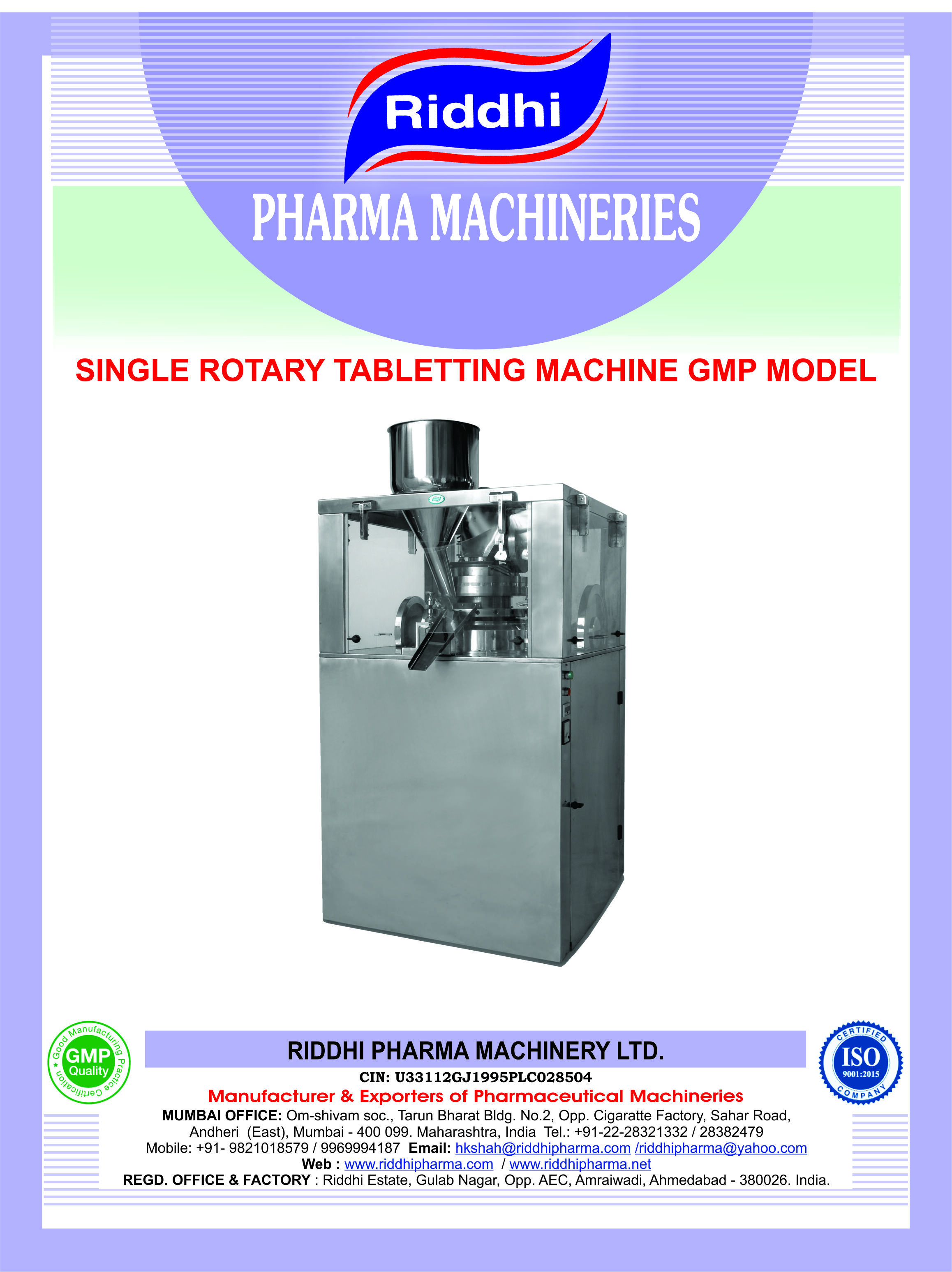

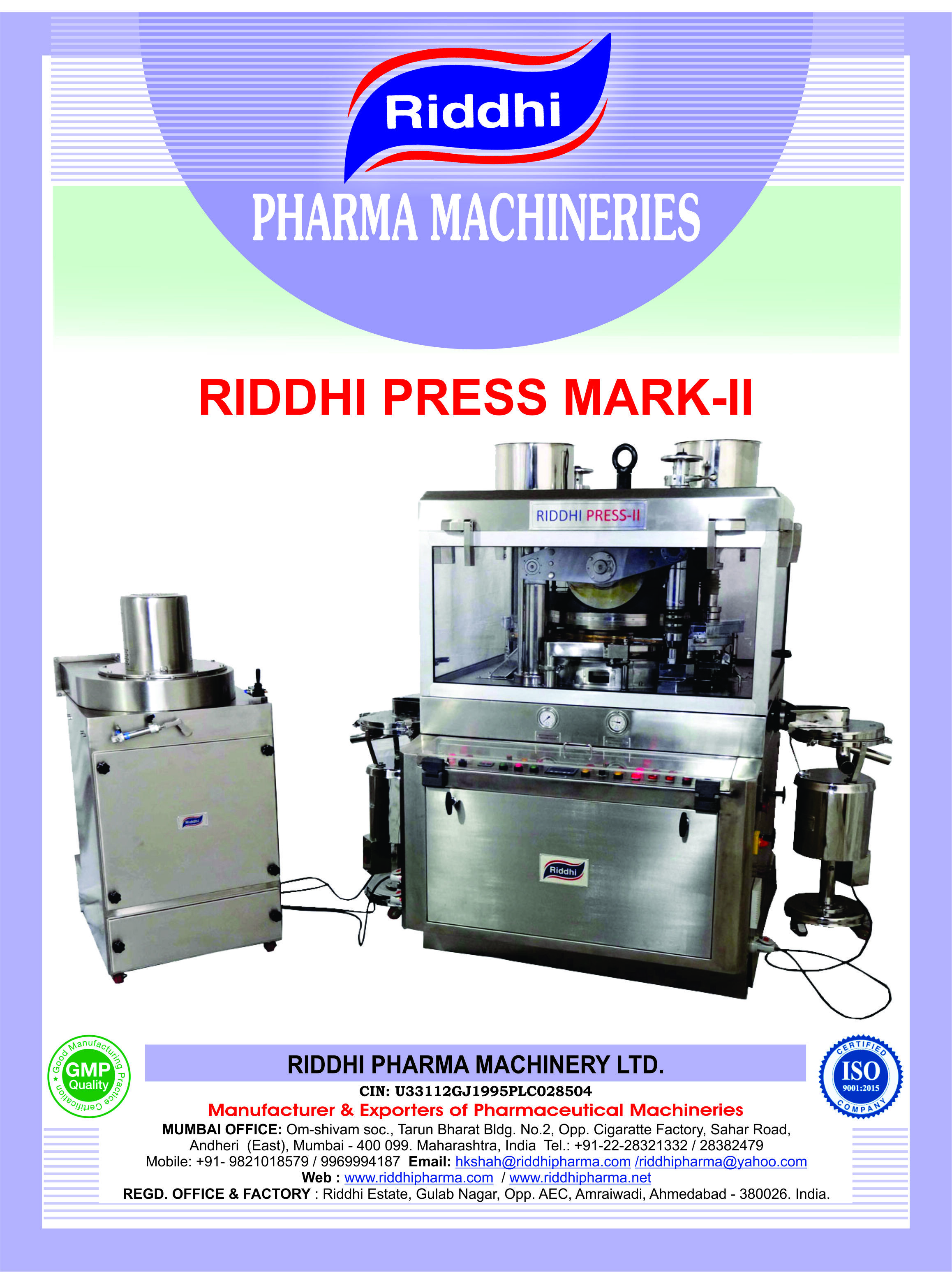

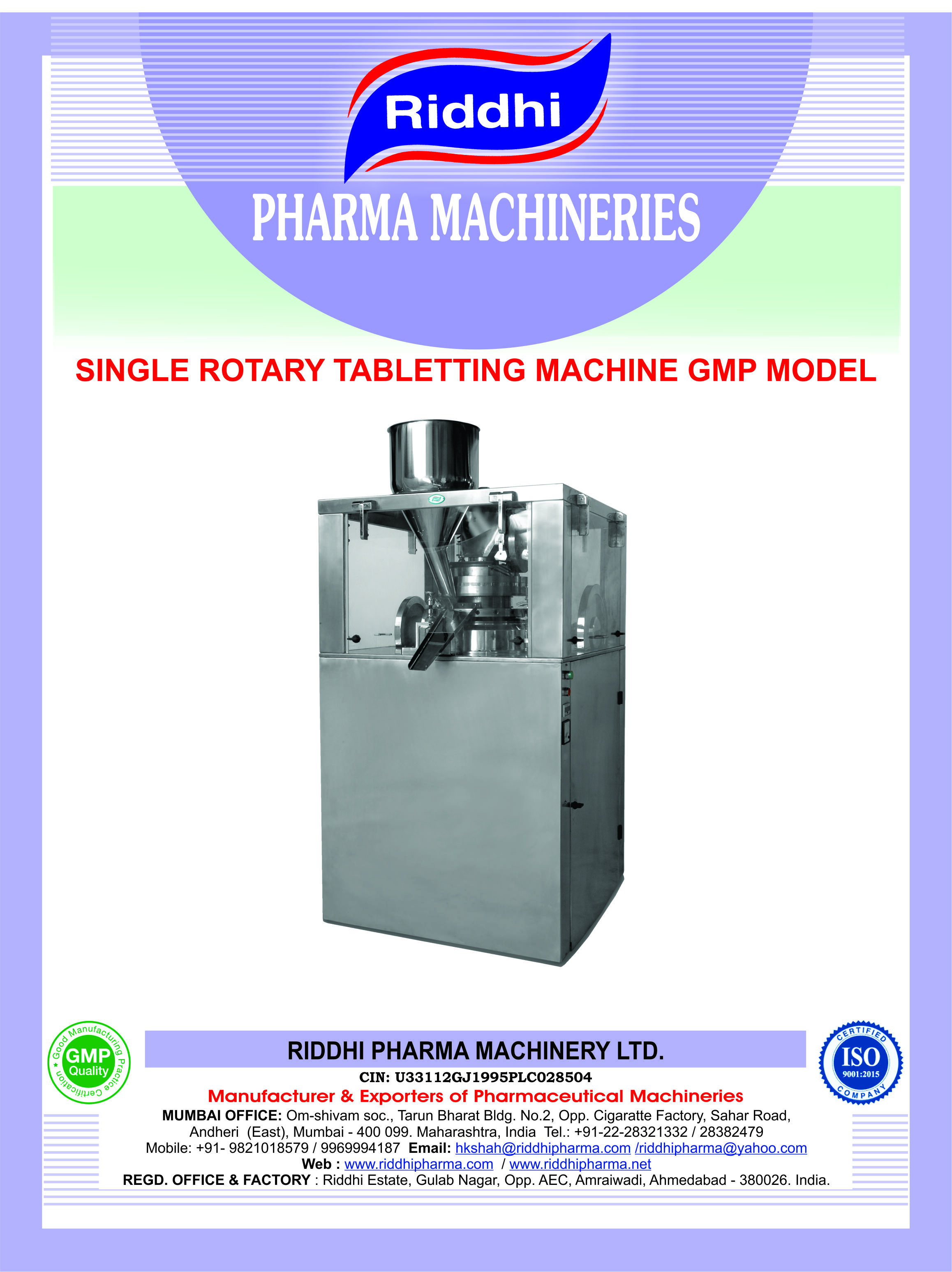

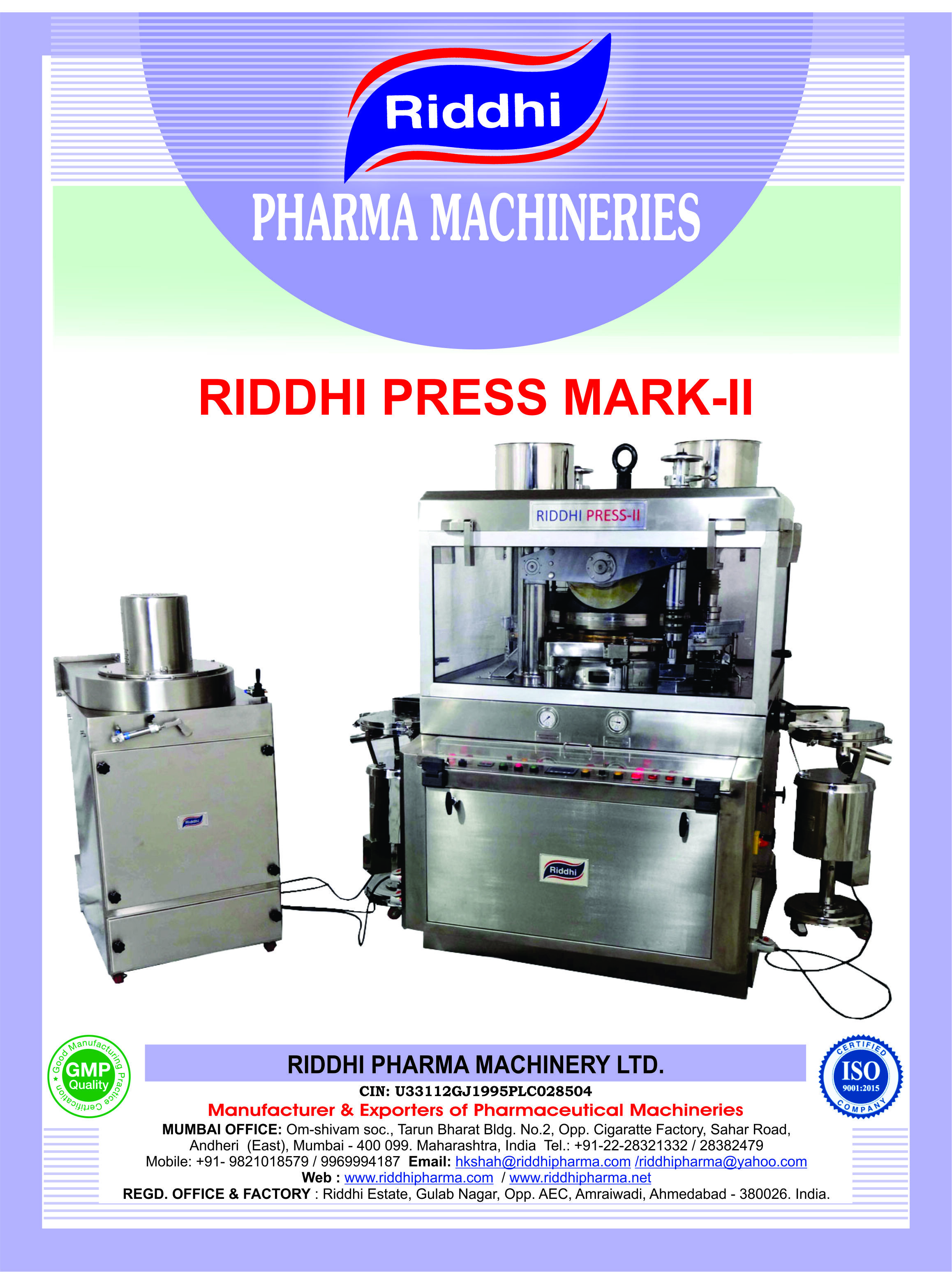

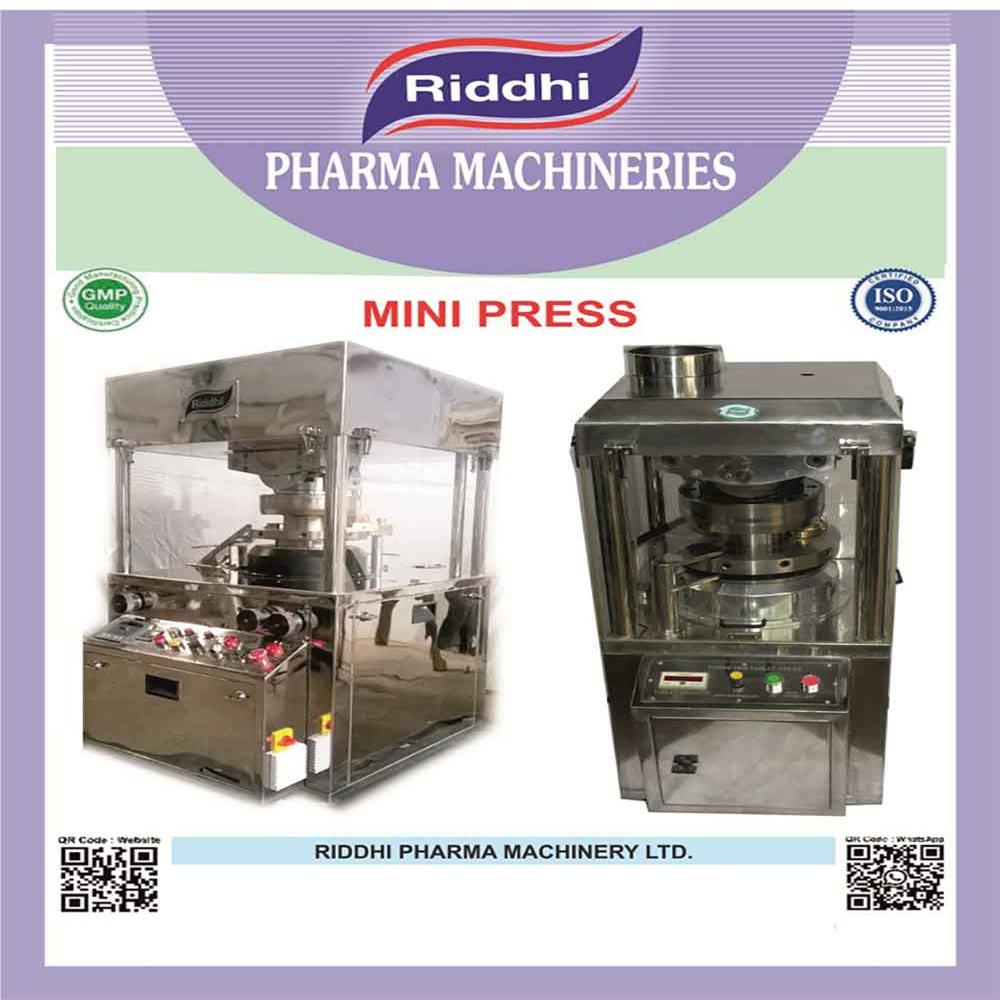

Tablet Compression Machine

Product Details:

- Type Tablet Pressing Machine

- Material Stainless Steel

- Control Mode Semi-Automatic

- Voltage 440 Volt (v)

- Color Silver

- Warranty 1 Year

- Click to View more

Tablet Compression Machine Price And Quantity

- 3 Unit

- 525000 INR/Unit

Tablet Compression Machine Product Specifications

- Silver

- Semi-Automatic

- Stainless Steel

- Tablet Pressing Machine

- 440 Volt (v)

- 1 Year

Tablet Compression Machine Trade Information

- JNPT PORT MUMBAI

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 3 Unit Per Month

- 8 Week

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Fulfilling the varied requirements of the market we are also known as a reckoned manufacturer and exporter of Tablet Compression Machine These machines are used extensively in the pharmaceutical and sweet industry for compressing tablets of various shapes and sizes Our offered machines are available for the customers in various specifications with an aim to fulfill their diverse requirements This Tablet Compression Machine is constructed out of CI body and CI middle system

Features

- Double Sided lifting cams

- Square GMP Model

- Very rigid Gun metal Feed frame

Further details

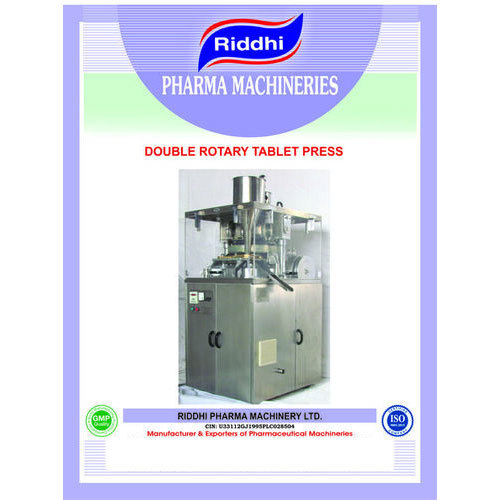

- Tablet Compression Machine Double Rotary Tablet Press RMB4

Application

- Square GMP Model

- CI Body and CI Middle plate

- Paint free tablet manufacturing zone

- Turret of SG Iron Special Grade Casting

- Separate centre pillar of CI graded casting

- Disc type friction clutch start system

- Upper Punch Penetration system

- Electronic Digital Tablet cum RPM Counter

- Inter lock switches to all Guards

- Double Sided lifting cams

- Lower Guard of Stainless Steel Upper Guards of Acrylic Material

- Aluminum Turret Guards 13 Effective Dust Extraction Nozzles

- Imported needle roller bearing provided at the bottom of turret

- Redesigned Variable Speed Pulley One shot Lubrication System and Anti Vibrating Mounts are provided

- Very rigid Gun metal Feed frame both identical with sufficient height to avoid spill over of powder

- Turret with key slots essential for shaped tooling provided on 27 33 35 37 station machine optional on 41 45 station machine

- Separate front and rear take off chutes to avoid any blockage or double compression resulting in accident

- Oil groove on top face of turret for collection of excess oil

- Special Additional Features

- SS Turret Die Middle Plate

- AC Frequency Drive for Main Motor

- Square GMP Model with SS Lower Half Enclosures

- Safety Switches at Acrylic Guards

- Automatic Centralized Lubrication System

- Upper Punch Penetration

| Model No. | RDMB4 27 | RDMB4 27D | RDMB4 35 |

| No. of Stations | 27 | 27 |

|

| Type of Tooling Die | B | D |

|

| Type of Tooling Punch | B | D |

|

| Max. Output | 129,600 Tabs./Hr. | 129,600 Tabs./Hr. |

|

| Max. Tablet Diameter | 23mm | 16mm |

|

| Max. Depth of Fill | 17.5mm | ||

| Max. Turret Speed | 40 RPM | ||

| Max. Op. Pressure (Main) | 3 Piece. | 10 Tons | 7.5 Tons |

| Turret Construction | 3 Piece Construction. | ||

| Turret Material of Construction (M.O.C.) | Die Plate of S.S.316 Quality and rest of Special Grade Cast Iron Quality | ||

| Upper Punch Penetration | 2 to 6mm | ||

| Pre-Compression Pressure | Not Available. | ||

| Force Feeding System | Available (Optional) | ||

| Main Motor | 5 HP, 380 / 220V, 50 / 60 Hz., 3 Phase Non FLP Type | ||

| Overall Dimensions | 43 x 38 x 64(H) when Guards are Closed Approx | ||

|

| 63 x 58 x 84(H) when Guards are Open Approx. | ||

| Net Weight | 1250 Kgs. Approx | ||

| Gross Weight | 1800 Kgs. Approx | ||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+