Xtruder

Product Details:

Xtruder Price And Quantity

- 1 Number

- 325000.0 INR/Number

Xtruder Trade Information

- MUmbai

- Telegraphic Transfer (T/T)

- 2 Number Per Week

- 8 Week

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

PURPOSE :

To convert mixed dough to fixed diameter extrudes / needles.

FUNCTION :

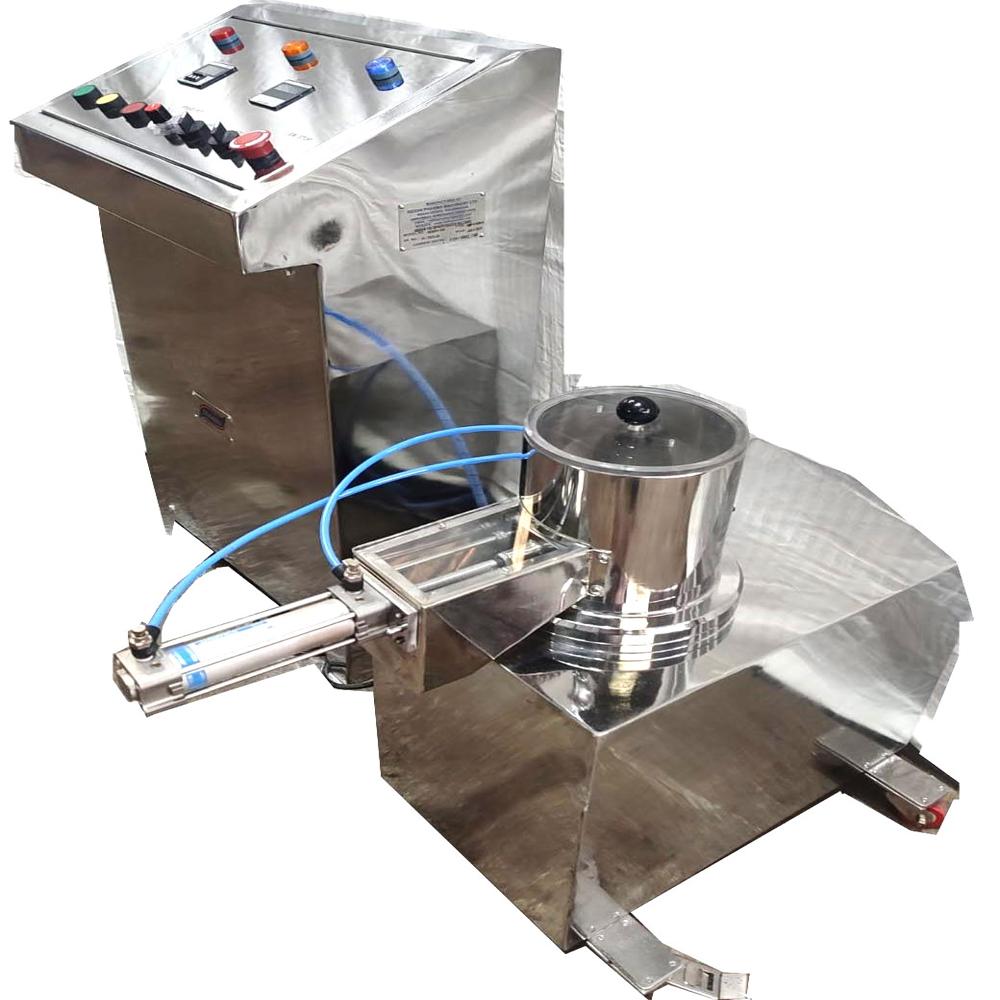

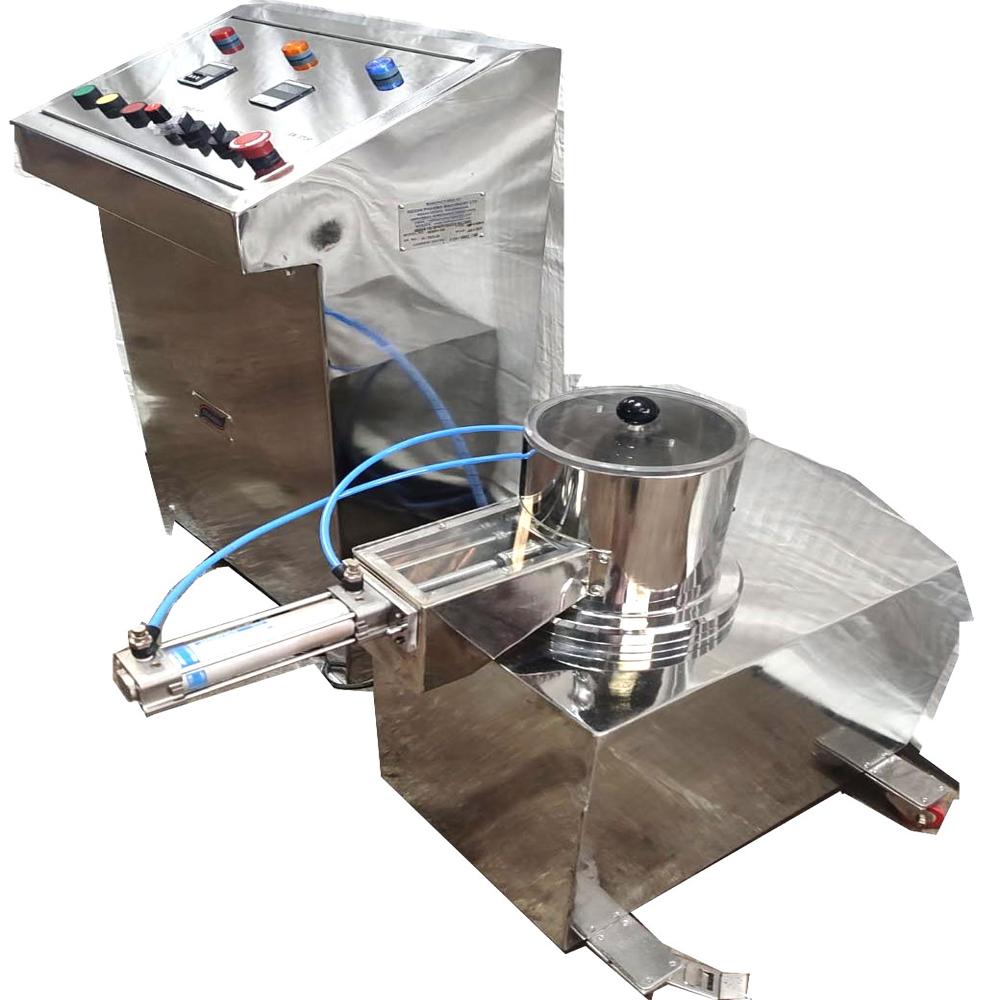

RIDDHIXtruder has two major parts one is the Die roller of required size, and the other is pressuring (Knurling) roller, needles coming out of the extruder are cut into definite length by the cutter. The size of the Die roller can vary from 2 5mm. For conversion of needles i.e. into spherical spheres/pellets a Spheroidizer needs to be used in conjunction with the extruder.

SPECIFICATIONS :

Model No.:RDXT 130 GMP

Type :Die Roller Type (Knurling & Die Roller)

Minimum capacity:2.5 Kgs. / batch

Maximum capacity:200 - 300 Kgs./hr. output on continuous basis.

Contact Parts:S.S. 316.

Non-Contact parts:S.S. 304 covered / cladded.

Finish:Dull matt finish from outside & internal parts mirror polished.

Main Motor:7.5 H.P. / 1400 RPM / 3 Non FLP Type.

MACHINE PART DESCRIPTION :

The main body is machined, it is constructed in S.S. 304, covered / Cladded. Its main purpose is to hold the extrusion assemblies, motor, gear box and controls for material processing. The body is of table-top design a appropriate table needs to be constructed for installation of the equipment.

1.EXTRUSION ASSEMBLY

Material of construction of all parts and material use for sub-assemblies:

1.1 Die roller - S.S. 316.

1.2 Knurling roller / Pressuring roller - S.S. 316.

1.3 Cutter / Scrapper blade - S.S. 316.

1.4 The assembly is rigidly closed and easy for operation.

1.5 Bearings are isolated with Teflon gaskets, so that do not come in contact with product.

1.6 All gaskets in Food grade rubber.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free