Rapid Mixer Granulator

Product Details:

- Type Other

- Material POWDER

- Computerized Yes

- Control Mode Automatic

- Voltage 440 VOLTS Volt (v)

- Power 3 PHASE Milliampere (mA)

- Weight (kg) 750 Kilograms (kg)

- Click to View more

Rapid Mixer Granulator Price And Quantity

- 1 Unit

- 650000 INR

Rapid Mixer Granulator Product Specifications

- Automatic

- 3 PHASE Milliampere (mA)

- Yes

- 750 Kilograms (kg)

- Other

- POWDER

- 440 VOLTS Volt (v)

- 6 X 7 X8 Foot (ft)

- STAINLESS STEEL

- ONE YEAR WARRANTY

Rapid Mixer Granulator Trade Information

- Cash in Advance (CID)

- 2 Unit Per Month

- 1 Months

- South America, Middle East, Africa, Central America, Western Europe, Asia, Eastern Europe, North America, Australia

- All India

Product Description

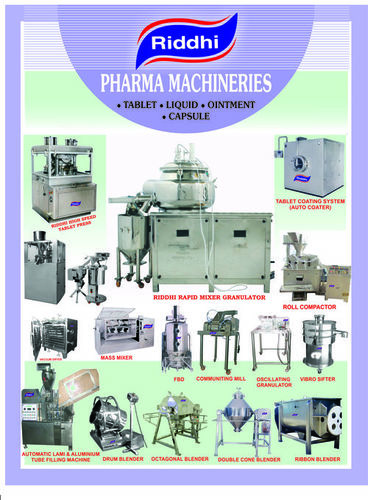

Rapid Mixer Granulator

Rapid Mixer Granulator is widely used in the domain of Pharma for the purpose of Wet Granulation. Also recognized as High Shear Mixer, this is perfect for creating wet mass that is milled by blades for converting it into uniform granules. It is available in 4 models such as RDRMG-100, RDRMG-250, RDRMG-400 and RDRMG-150 from 100 to 600 litres.

This is designed to ensure homogenous mixing of wet as well as dry powders. In addition, it is also used for deaglomeration of wet mass as well as swift dispersion of the binding agents. This ensures to provide dust free processes of high free flowing dosing particles along with maximum uniformity of granule size. It comes with AC frequency control to manage bottom driven impeller mixer having 3 or 4 blades. With special scrape side design as well as modern chopper, it ensures to create uniform granules.

Default Pneumatic discharge assembly along with pneumatic bowl lifting ensures to make the process easy and swift. It comes with different capacities from 5Ltrs to 1200Ltrs.

Working Principle:

This is a mixing unit equipped with bottom entry agitator as well as side mounted chopper for granulation. This is perfect for preparing dough and granulation, dry blending, wet mixing, etc. It works on the working principle of stirring of the contents at moderate speed. Its specially profiled cutter blade works at a very high speed into the wet mass.

Rapid Granulators:

- Standard Processing Duration:

- Dry Mixing approx 3 - 5 Mins

- Wet Mixing approx 5 - 10 Mins

- Wet Granulation approx 5 - 10 Mins

- Discharge approx 1-15 Mins

The given time may vary according to the material:

- Improved Processing:

- Also available with PLC'S.

- Available in 10Ltrs., 25Ltr. / 50Ltr.

- Bowl shape design with no dead spaces

- Easy scale up as well as scale down between the machine The given time may vary according to the material sizes

- Even distribution of the formulation ingredients

- High working capacity of 80% to 40% of bowl volume

- Short mixing as well as granulation time

- The process parameters are derived in the Lab/Pilot into production machines

Model | RDRMG-100 | RDRMG-150 | RDRMG-250 | RDRMG-400 |

Gross capacity (ltrs.) | 100 | 150 | 250 | 400 |

Working capacity (lits.) | 80 | 120 | 200 | 320 |

Batch Size in Kg. | 20-30 | 30-60 | 50-100 | 75-150 |

Mixer Motor | 7.5 HP / 10 HP | 10 HP / 15 HP | 22.5 HP / 30 HP | 35 HP / 40 HP |

Mixer RPM | 75/11500 | 750/1500 | 750/1500 | 750/1500 |

Granulator Motor | 2 HP / 3 HP | 3 HP /5 HP | 3 HP / 5 HP | 5 HP / 7.5 HP |

Granulator RPM | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

Length (cm) | 240 | 240 | 270 | 280 |

Width (cm) | 210 | 210 | 220 | 240 |

Hight (Lid closed) (cm) | 200 | 200 | 210 | 215kg |

Net Weight (approx) | 1400 kg | 1600 kg | 1800 kg | 2400 kg |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+