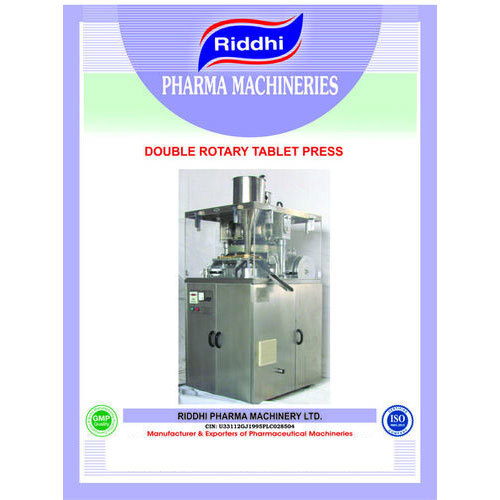

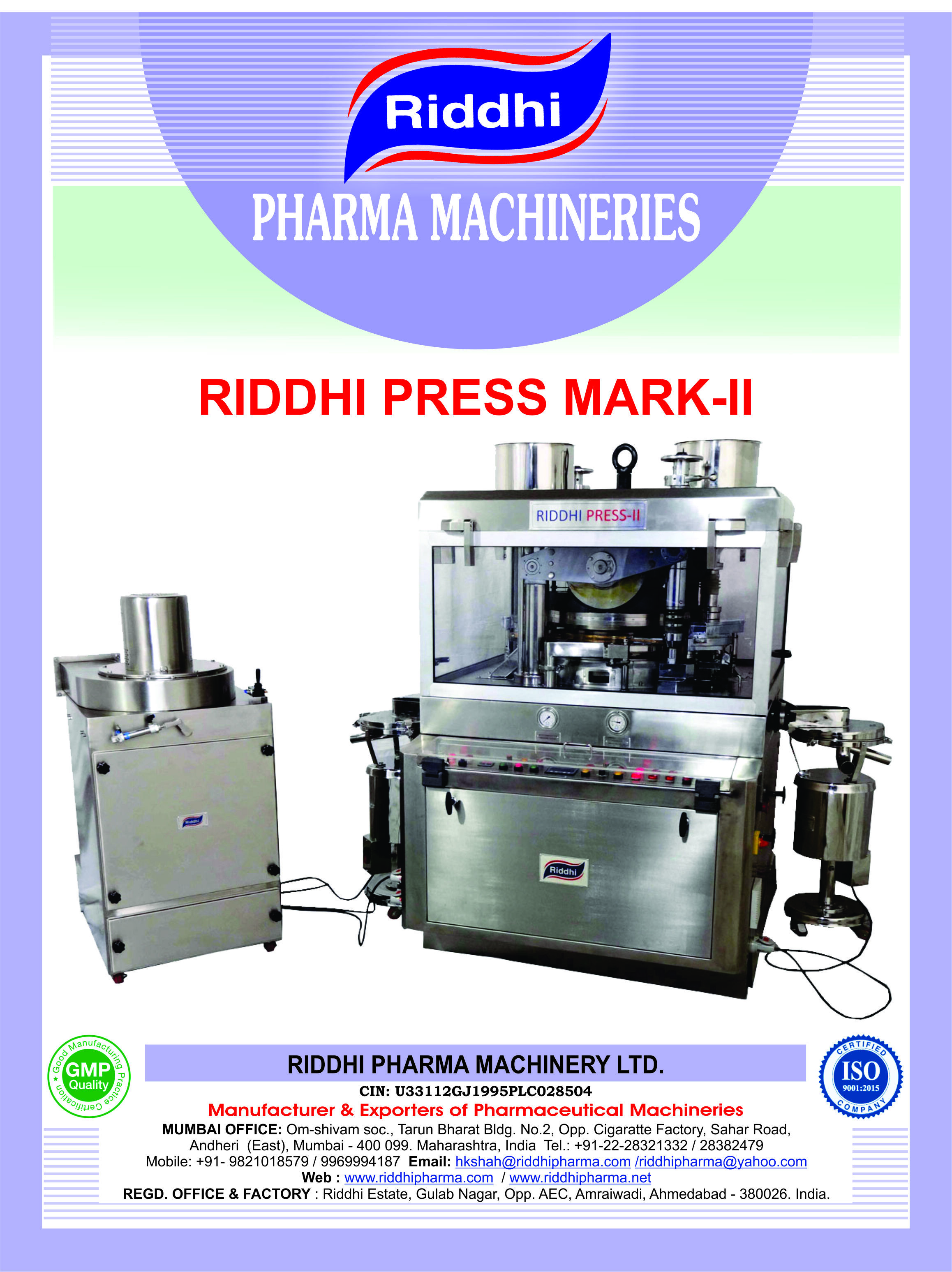

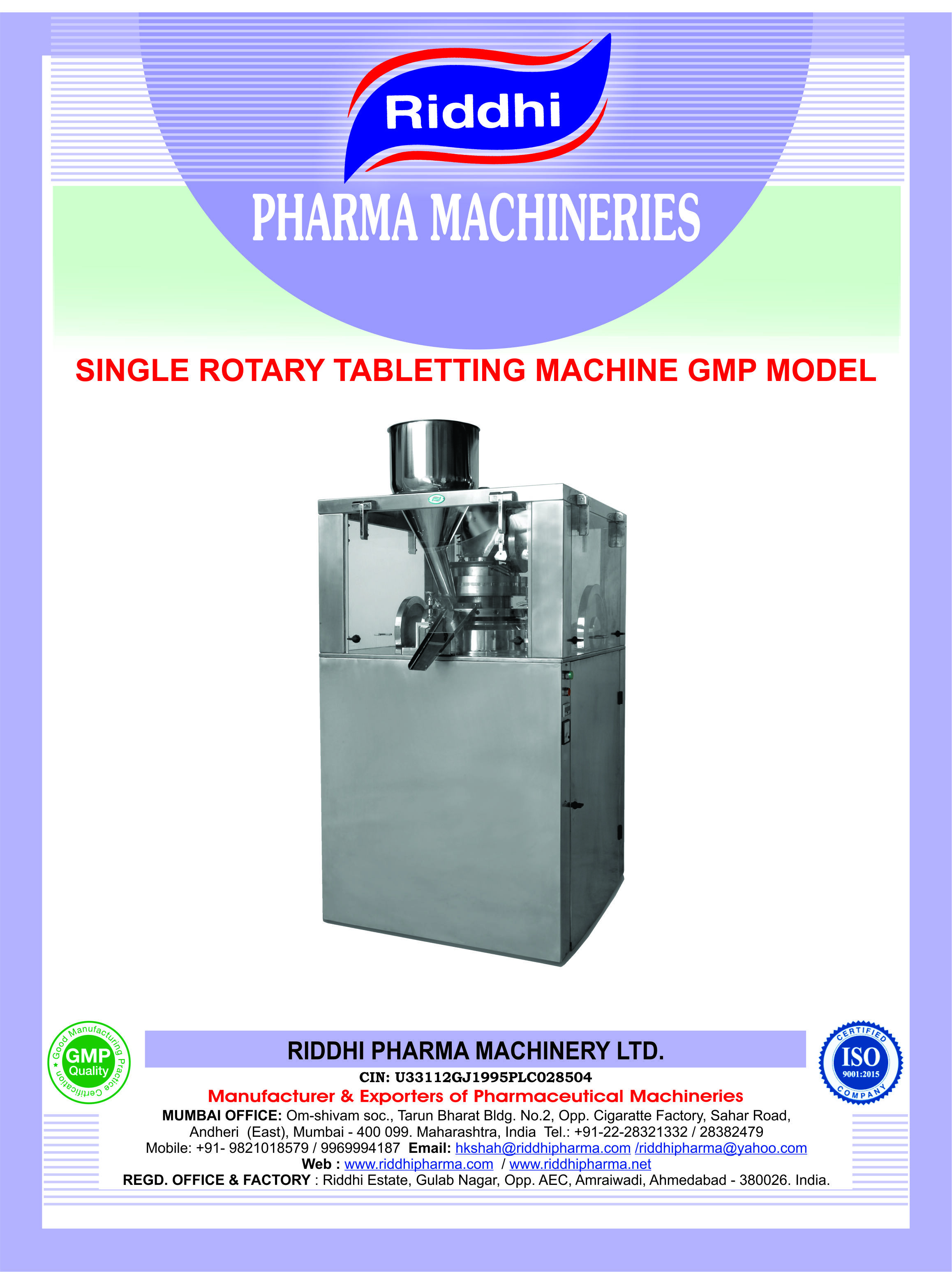

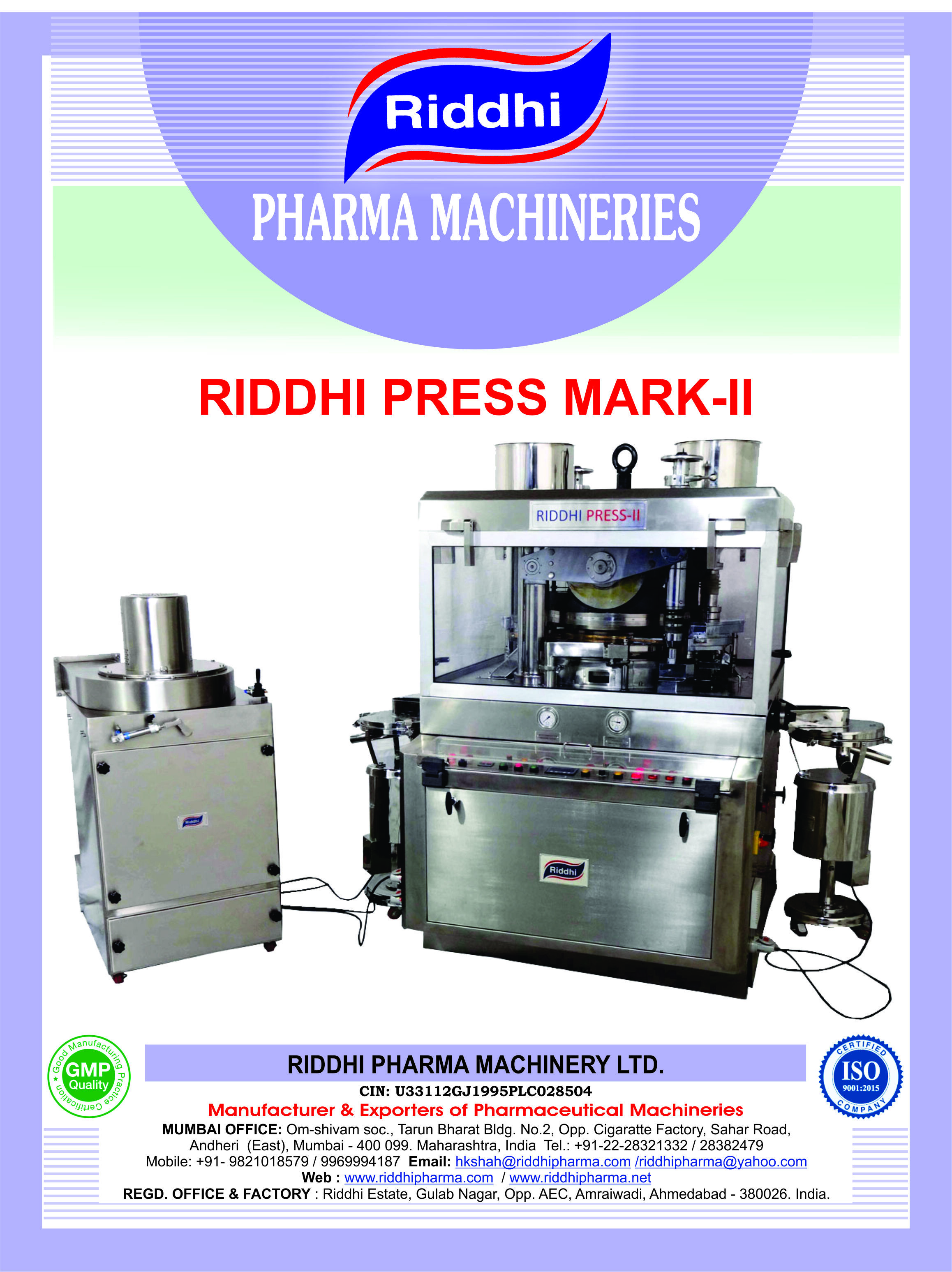

Rotary Tablet Press

Product Details:

- Type Tablet Pressing Machine

- Material Stainless Steel

- Control Mode Semi-Automatic

- Voltage 440 Volt (v)

- Color Silver

- Warranty 1 Year

- Click to View more

Rotary Tablet Press Price And Quantity

- 3 Unit

- 738000.00 INR/Unit

Rotary Tablet Press Product Specifications

- 440 Volt (v)

- Silver

- Stainless Steel

- 1 Year

- Tablet Pressing Machine

- Semi-Automatic

Rotary Tablet Press Trade Information

- JNPT PORT MUMBAI

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 3 Unit Per Month

- 810 Week

- Contact us for information regarding our sample policy

- SEA WORTHY PACKING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO 9001:2015, GMP CERTIFICATE

Product Description

Specification

Number Of Station | 27 station |

Model Number/Name | RDDRTM |

Machine Type | MECHANICAL |

Material | MS , CASTING |

Automation Grade | Automatic |

Phase | 3 PHASE |

Voltage | 440 VOLTS |

Warranty | ONE YEAR WARRANTY |

Belt Type | TIMER BELT |

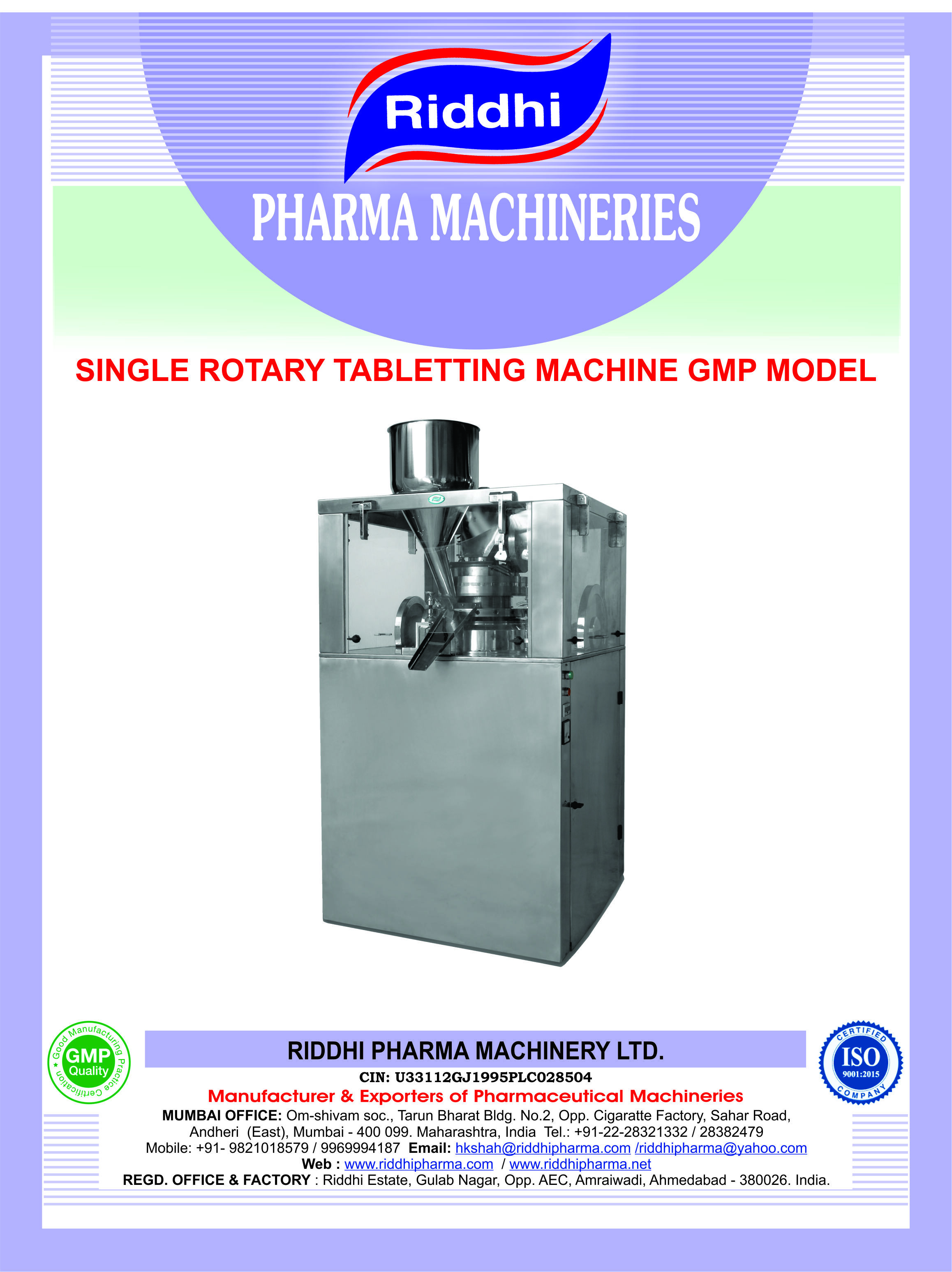

Technical Specification

Models | RDMD4-27 | RDMB4-35 | RDMB4-45 |

No . Of Stations | 27 | 35 | 45 |

Tooling | "D" | "B" | "BB" |

Output Tablets Per Min. | 900-2268 | 1167-2940 | 1500-3781 |

Max . Depth of Fill | 20 mm | 17.4 mm | 17.4 mm |

Max . Tablet Dia | 25 mm | 16 mm | 11 mm |

Max. Upper Punch Entry | 8 mm | 8 mm | 8 mm |

Min. Upper Punch Entry | 1.5mm | 1.5mm | 1.5mm |

Max . Operating Pressure(Main) | 6.5 Tons | 6.5 Tons | 6.5 Tons |

Main Motor | 5HP/1440 RPM / 3 | 5HP/1440 RPM / 3 | 5HP/1440 RPM / 3 |

Overall Height | 1790mm | 1790mm | 1790mm |

Overall Width | 1000mm | 1000mm | 1000mm |

Overall Depth | 1040mm | 1040mm | 1040mm |

Net Weight | 1143 Kgs | 1143 Kgs | 1143 Kgs |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free